In recent years, although our country's injection molds have developed rapidly in terms of technology and quality, there are still problems such as supply and demand contradictions, unbalanced industrial development, and insufficient innovation capabilities that are difficult to solve in the short term. The current market

competition is very fierce, and there are more and more homogeneous products. In order to win in the fierce market competition, many companies are developing new products, and the development of new products needs to be tailored to the injection mold. custom made. As a result, the customized processing of injection molds has become a new trend in the development of the mold industry.

Many companies may encounter a series of problems, such as different quality of OEM products, inconsistent samples provided with products, speed and quality not keeping up, and delayed delivery cycle. It is the appearance of these problems that makes the customized processing of injection molds a new trend in the mold

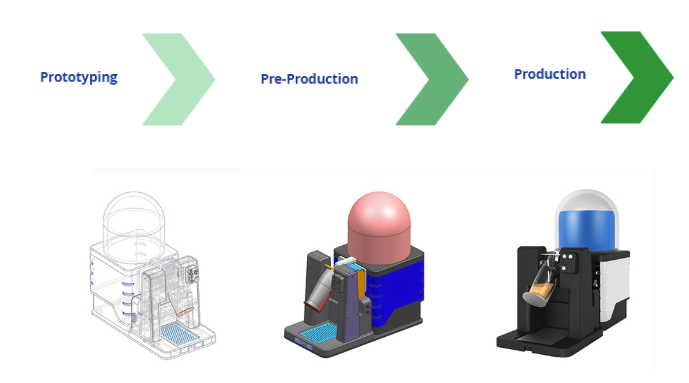

industry. Allowing enterprises to customize injection mold processing according to their own needs. Of course, some companies have their own R&D teams. They hand over the design drawings of new products to injection mold manufacturers. The mold manufacturers design molds according to the design drawings of new products, and then process and produce them.

Similarly, when the injection mold is customized and processed, the manufacturer can choose the appropriate material according to its own requirements, which can ensure the quality of the injection mold, ensure the quality of the products in the future, and also increase the service life of the injection mold.

Of course, when enterprises choose processing manufacturers for injection mold customization, they must also choose powerful manufacturers.

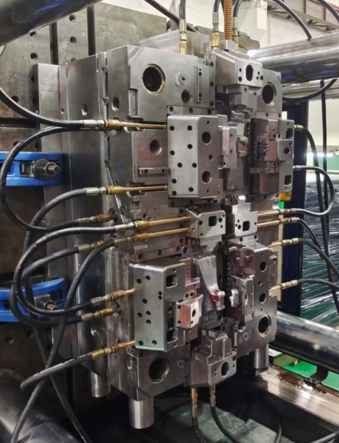

Chapman maker is a technology-based OEM specialized in providing high-precision injection molds, as well as one-stop injection molding, finished product assembly and other businesses for the global automotive industry, consumer appliances, medical and health, industrial appliances, communications electronics and other industries. . We have accumulated rich experience in precision mold processing and precision injection molding of engineering plastics. Be able to fully master

composite precision process combination technology, precision detection

technology, and use CAD/CAE, UG technology. During the transition from"precision manufacturing" to "scientific and technological innovation", Chapman maker will gradually decompose its business focus to the direction of product development, information management, and automated manufacturing capacity building.

If the customized processing of injection molds is a new trend in the development of the mold industry, then Chapman maker is at the forefront of the mold industry.

For more technical questions, you can consult Chapman Maker team and provide professional technical support.

Email: info@chapmanmaker.com

Post time: Mar-05-2022