When some customers develop products or new product designs, they often only focus on product research and development or price in the initial stage, ignoring communication with mold manufacturers. After the product design plan is initially determined, it is necessary to communicate with the mold manufacturer in advance.

1. There are many types of molds. According to different requirements of parts material, physical and chemical properties, mechanical strength, dimensional accuracy, surface finish, service life, cost performance, etc., different types of molds are selected for forming.

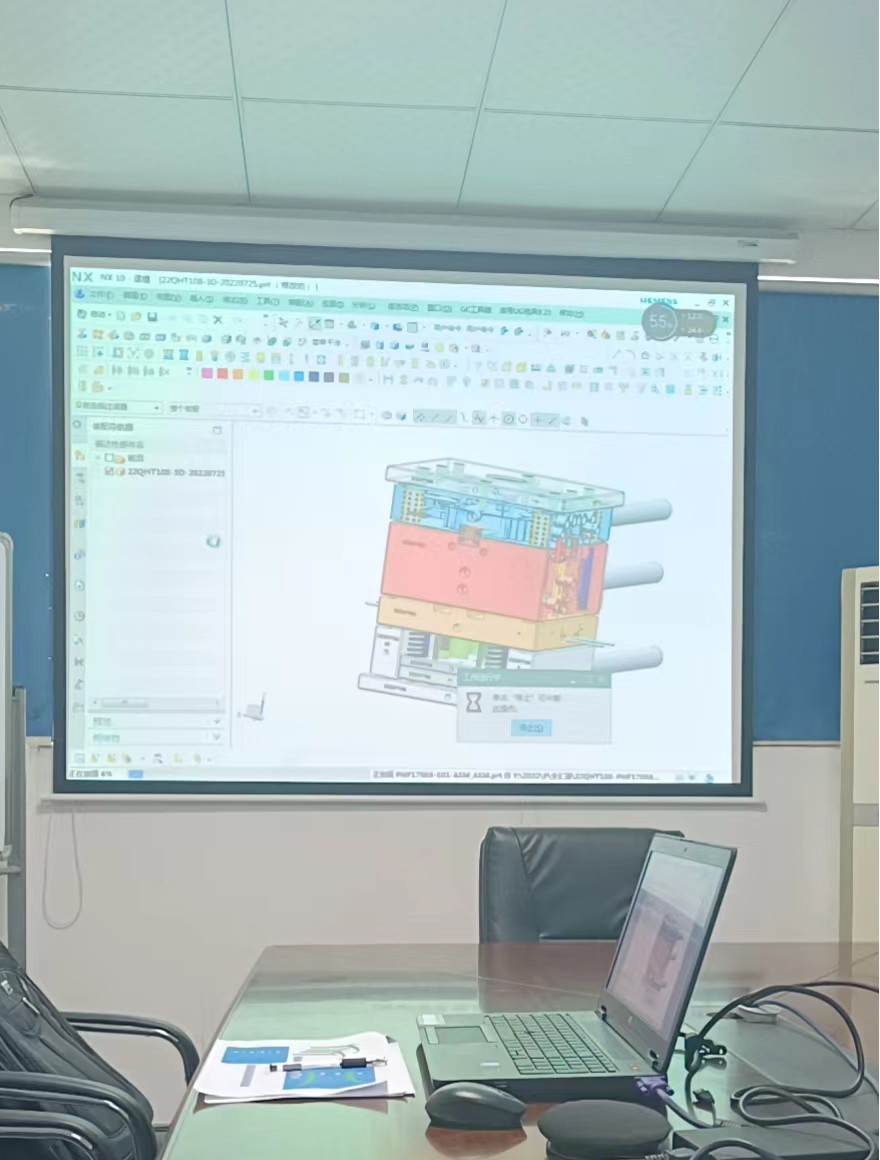

2. Molds with high precision requirements need to use high-precision processing equipment, and the mold material and forming process requirements are relatively strict, and mold software such as CAD / CAE / UG should be used to design and analyze.

3. Some plastic products have special requirements in the design, and the mold structure is more complicated. The mold manufacturer also needs to use advanced processes such as hot runner, gas-assisted molding, and oil cylinder.

4. Manufacturers should have CNC, EDM, wire cutting machine tools and CNC copy milling equipment, high-precision grinding machines, high-precision three-coordinate measuring instruments, computer design and related software.

5. Generally, large-scale stamping dies (such as automobile cover molds) should consider whether the machine tool has a side blanking mechanism, or even side lubricants, multi-station progressive, etc. In addition to stamping tonnage, punching times, feeding devices, machine tools and mold protection devices should also be considered.

6. The manufacturing methods and processes of the above-mentioned molds are not possessed and mastered by every mold manufacturer. When choosing a cooperative manufacturer, you must understand its processing capabilities, not only by hardware equipment, but also by management level, processing experience and technical strength.

7. For the same set of molds, there is sometimes a big gap between the quotations of different manufacturers. You should not pay more than the value of the mold, nor less than the cost of the mold. Mold manufacturers, like you, want to make reasonable profits in their business. Ordering a set of molds at a much lower price can be the start of trouble. Users must start from their own requirements and comprehensively measure.

Chapman Mould Co., Ltd. is a very professional manufacturer of injection molds. We continue to innovate and optimize the mold structure to provide high-quality injection molds as our mission. For injection molds, many manufacturers can do it now. But doing it doesn't mean you can do it well. No matter what, only the most professional is the most trusted by customers. As a professional mold manufacturer, we have continuously summed up and explored in many years of mold production experience, and now we have a complete set of injection mold design concepts and manufacturing processes. Every detail in the design has been carefully analyzed and certified, and the workmanship is also placed in the hands of a manufacturing master who has been manufacturing injection molds for many years.

Chapman Mould has always insisted on doing the most professional things and providing customers with the most worry-free service. I believe our professionalism can solve your problems!

Have more injection mold questions feel free to contact us at info@chapmanmaker.com !

Post time: Nov-29-2022